Vertical Turning And Milling Machining Center

Brand QIER WAJI CNC MACHINE

Product origin CHINA LIAONING

Delivery time 3 months

Supply capacity 2-5 units per month

1. Due to the simple structure of the turning machine, it is very easy to clamp the workpiece. Common fixtures, such as flat jaws, pressure plates, indexing heads, and rotary tables, can be used to clamp workpieces. The vertical lathe machine's clamping positioning and repeated positioning operations are very convenient and simple.

2. The structural design of the turning machine is conducive to cooling, because the coolant is sprayed from top to bottom and can be directly sprayed onto the high-temperature workpiece and tools during machining.

Comparative advantages of vertical lathe machine:

1. Process efficiency: vertical lathe machine can integrate various processes such as turning, milling, drilling, and tapping, which can greatly shorten the production cycle.

2. Machining accuracy: vertical lathe machine only needs one clamping, which can effectively avoid the superposition of positioning deviations.

3. Cost control: 1 vertical lathe machine can replace 3-5 traditional equipment functions, reduce procurement costs and save floor space.

4. Flexible production: vertical lathe machine can quickly switch processing categories by changing tools and adjusting procedures, without the need to significantly adjust the equipment to adapt to the flexible production needs of multi-variety orders.

Processing method of vertical turning center:

Vertical turning center is a kind of composite processing equipment. The processing methods of vertical turning center include turning, milling, turning and milling composite technology, automatic tool change and CNC control. Vertical turning center can meet the processing needs of different workpieces.

Quality standards of vertical turning lathe machine:

Our vertical turret lathe is produced in accordance with a strict quality control system and is certified to international standards including CE and ISO 9001. Ensure that every vertical lathe machine that leaves the factory has excellent reliability and safety performance.

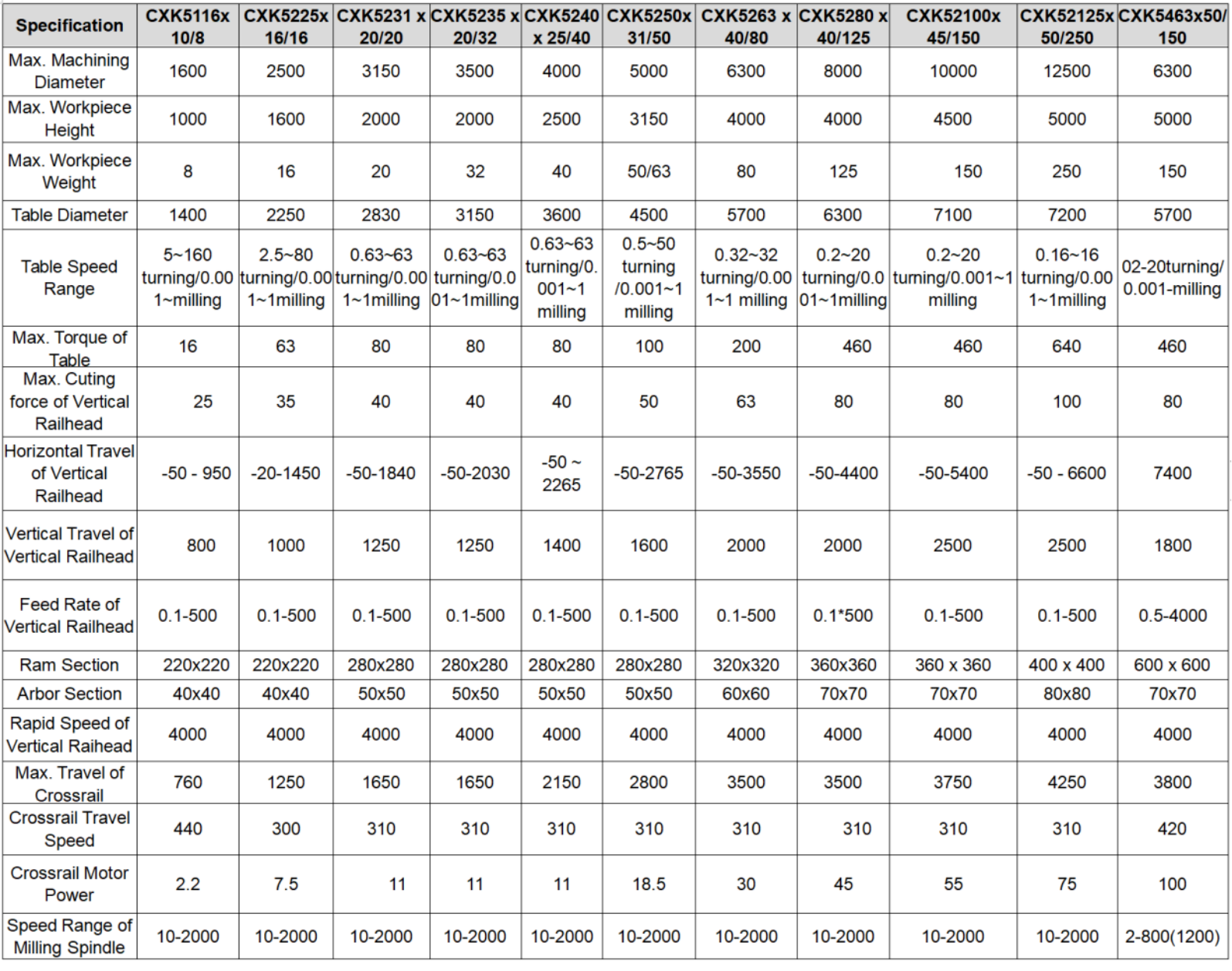

Specifications of turning machine:

Why choose vertical turret lathe:

Choosing vertical turret lathe means choosing efficient, precise and flexible production. Vertical turret lathe can complete multiple processes with one clamping, and the processing efficiency is greatly improved. Vertical turret lathe can effectively avoid the cumulative errors caused by multiple clamping, and the machining accuracy far exceeds that of traditional equipment. Facing complex curved surfaces and special-shaped parts, vertical turret lathe's multi-axis linkage function can flexibly adjust the tool angle to achieve high-precision machining. Moreover, vertical turret lathe covers a small area, and one equipment can support multiple units. Vertical turret lathe can reduce the cost of enterprise equipment procurement and site leasing, easily adapt to the needs of multi-variety and small-scale mass production, and help enterprises improve their competitiveness.

Introduction of turning machine:

CXK52, CXH52, CXK54 series turning machine are high-end processing equipment. Turning machine suitable for large parts with high machining accuracy requirements and long process routes. This process meets the needs of users for Louhe chemical processing. The turning machine is equipped with functional components such as iron, town function, C-axis function, tool friction, tool setting instrument, tool breakage detection, etc. Turning machine can meet the needs of high-end users.

Advantages of turning machine:

1. Due to the simple structure of the turning machine, it is very easy to clamp the workpiece, and common fixtures can be used, such as: flat pliers, press, plate, indexing head, rotary table and other fixtures are used to clamp the workpiece, and the clamping positioning and repeated positioning of the workpiece are very convenient and simple.

2. The structural design of the turning machine is conducive to cooling, because the coolant is sprayed from top to bottom and can be directly sprayed to the high-temperature process during machining.parts and knives.

3. The structure of turning machine is relatively simple, the running track of the tool can be observed, debugging, observation and modification of parameters are also convenient, and it is also convenient for workpiece measurement. It is convenient to stop processing and modify immediately when problems are found.

4. turning machine is easy to remove chips when machining flat workpieces, and the generated chips are directly washed away by the sprayed coolant, which prevents the chips from scratching the surface of the workpiece during cutting.

5. Compared with the horizontal machining center, the structure of the turning machine is simpler, the floor area is smaller, and the price is also cheaper.

Application scenarios of turning machine:

1. Aerospace: turning machine is suitable for high-precision machining of aviation engine blades, chassis, landing gear and other parts to meet stringent surface quality and dimensional accuracy requirements.

2. Automobile manufacturing: turning machine can efficiently process automobile engine blocks, gearbox housings, and precision shaft parts to help improve the production efficiency and quality of core automotive components.

3. Mold manufacturing: turning machine can complete the milling and turning of complex mold cavities and cores, shorten the mold development cycle, and improve the accuracy and service life of the mold.

4. Energy industry: turning machine is used to process key parts of energy equipment such as steam turbine blades, pump bodies, valves, etc. to ensure the reliability and stability of the equipment.

Purchase guide of vertical lathe machine:

1. According to the type, size, accuracy requirements and process complexity of the workpiece, lock the adapted vertical lathe machine.

2. Pay attention to the turning machine's spindle speed, tool magazine capacity and tool change speed to ensure the efficient processing of vertical lathe machine.

3. Compare the price of vertical lathe machine with energy consumption and maintenance costs, and give priority to the vertical lathe machine with low energy consumption and easy maintenance.

Installation of vertical turning center:

Vertical turning center needs to strictly follow the standardized process. First of all, choose a workshop site that is flat and stable, and the carrying capacity of the foundation meets the requirements of vertical turning center, and use a level meter to calibrate the level of the vertical turning center to ensure that the base of the vertical turning center is reliably fixed to the ground. Then connect the CNC system, servo motor, cooling system and other components of the vertical turning center according to the electrical drawings. After completing the turning machine's mechanical and electrical installation, add lubricants and cutting fluids that meet the standards, start the vertical turning center for no-load test operation, and check whether the spindle speed of the vertical turning center, tool magazine tool change, and axis linkage functions are normal. Finally, the positioning accuracy and repeat positioning accuracy of the vertical turning center are calibrated by precision instruments such as laser interferometers to ensure that the vertical turning center is put into production in the best condition.

Operating procedures of turning machine:

1. Operation table setting: according to the processing requirements, the operation table and workpiece fixture are reasonably set up so that the workpiece is placed correctly, and the operation table setting meets the turning machine's safety requirements.

2. Start the turning machine: turn on the switch of the turning machine, wait for the turning machine to self-test the functions, and after confirming that the functions are normal, enter the processing program into the computer to start the operation of the turning machine.

3. Processing parameter setting: according to the processing requirements and the material and shape of the workpiece, appropriate processing parameter settings, are carried out to ensure the processing effect of turning machine.

4. Tool replacement: when the turning machine's cutting tool is worn out or needs to be replaced, first cut off the power supply of the turning machine, use the tool to remove the tool and install the new tool, and then reset the tool length and radius compensation of the turning machine.

5. Monitoring during processing: during the processing process, the processing quality of the workpiece must be continuously checked and necessary adjustments must be made to make the workpiece processing meet the requirements.

6. Operation after processing is completed: after processing is completed, first cut off the power supply and turn off the turning machine switch, and then clean up the vertical lathe machine's tools and workpiece fixtures in time, and record the operation of the turning machine.

Maintenance procedures for vertical lathe machine:

1. After using it every day, the vertical lathe machine should be cleaned, and the vertical lathe machine's guide rail should be cleaned and lubricated.

2. Regularly check the working condition of the vertical lathe machine lubrication system, keep the lubricating oil at a normal level, and replace or replenish the lubricating oil in time.

3. Regularly check the working condition of the electrical system of the vertical lathe machine to ensure that the vertical turret lathe can operate normally and deal with faults in the circuit in a timely manner.

4. Regularly check the wear of vertical lathe machine tools, and replace severely worn tools in time to keep the vertical lathe machine's cutting effect at its best.

5. Maintain the normal level of coolant, clean the cooling system and replace the coolant regularly to make the vertical lathe machine work normally.

6. Regularly check the appearance of the vertical lathe machine, If any main parts are loose or worn, they should be repaired or replaced in time.

FAQ:

Q: Can vertical turret lathe replace traditional lathes and milling machines?

A: Depending on the processing needs, vertical turret lathe can replace multiple traditional lathes and milling machines in conventional turning, milling and multi-process composite machining to reduce process turnover. However, for ultra-large single turning or milling tasks, vertical turret lathe still needs to be equipped with special equipment.

Q: There is a deviation in accuracy during processing, what may be the problems of vertical turret lathe?

A: Common reasons include: wear of the spindle accuracy of the vertical turret lathe, insufficient lubrication of the guide rail of the vertical turret lathe, drift of the CNC system parameters of the vertical turret lathe, loose clamping of the fixture of the vertical turret lathe, or the tool wear of the vertical turret lathe is not replaced in time. It is necessary to check the status of the core components of the vertical turret lathe one by one.

Q: What core skills do novices need to master to operate vertical turret lathe?

A: You need to be familiar with the programming logic of vertical turret lathe's CNC system, understand the process arrangement of turning or milling composite processes, and master the fixture clamping skills of vertical turret lathe and the daily inspection of vertical turret lathe.

Q: How long is the maintenance cycle of vertical turning center?

A: The basic maintenance of the vertical turning center is once a day. The spindle lubrication and tool magazine calibration of the vertical turning center are performed once a month. Vertical turning center's rail accuracy inspection and transmission component wear inspection are once a quarter. For details, please refer to the manual of vertical turning center.

Q: What materials is the vertical turning center suitable for processing?

A: The vertical turning center has a wide range of adaptability. Vertical turning center can process conventional metals such as aluminum alloy, carbon steel, and stainless steel, as well as difficult-to-process materials such as titanium alloys and superalloys.

Company Profile:

QIER MACHINE GROUP DALIAN WAJI CNC MACHINE Co., Ltd. is a joint-stock enterprise jointly invested by QIER Machine Group affiliated to China General Technology Group and the former DALIAN WAFANGDIAN MACHINE GROUP Co., LTD., (WAFANGDIAN HEAVY MACHINE) in 2003. The company is located in Dalian Changxing Island industrial park, the beautiful shore of Bohai Sea. Our company registered paid-in capital of 80 million, factory covers an area of 13 acres that is a modern garden factory.

Our company inherited the DALIAN MACHINE TOOL GROUP CO., LTD. WAFANGDIAN city for half a century of the machine tool manufacturing technology and talents. QIER MACHINE GROUP has abundant technical force and development manufacturing strength as the backing, a new management model and operation principle has been implemented, formed development-manufacturing-marketing rapid response system. Our company committed to build a mainly mechanical and electrical integration of high-tech enterprises.

The company take the initiative in the market and widely satisfaction the requirement raised by user, so far, have already continuously developed over 10 different kinds of CNC machines which have been widely used in the shipping industry,electricity generating and so on, in particular, the developing of vertical CNC multifunctional milling and boring machine has replaced the same type of abroad imported products in China.

The leading products include swiveling diameter ranging from 400mm to 5000mm single and double column vertical lathe both CNC and conventional type, our products have already sale over 30 different provinces and autonomous regions in civil market. marketing share of the same kind has already been over 40% for abroad. so far, we have already exported our products to 38 different countries and regions, many products have already filled the blank in China and come up to the world advanced level.

The company has already had a sales network spread all over China. We will keep our promise, good quality of products and have courage to take responsibility. Sincerely hope we can supply the best products, the best service in the most competitive price. Hoping establish multi-mode cooperation with new and old friends all around the world. Let us be the real partner.

Are you still worried about the low processing efficiency and insufficient accuracy of many processes? Choose our vertical turning lathe machine to solve all problems in one stop! This vertical turning lathe machine integrates turning, milling, drilling and other functions. Vertical turning lathe machine can complete the processing of complex parts in one clamping. Compared with traditional equipment, vertical turning lathe machine can reduce processing time and greatly improve production efficiency. Vertical turning lathe machine adopts advanced CNC system. Whether it is precision parts of aerospace or key parts of automobile manufacturing, vertical turning lathe machine can easily cope with it. The wide processing diameter range of the vertical turning lathe machine allows workpieces of different sizes to be processed with high precision on this vertical turning lathe machine. Vertical turning lathe machine can make complex surface machining a breeze. Our vertical turning lathe machine has been exported to 38 countries and regions, and is trusted by customers around the world. The vertical turning lathe machine is equipped with a high-speed tool magazine and a fast tool change time, which can further improve the processing efficiency of the vertical turning lathe machine. And we have a perfect after-sales service system to escort you to use the vertical turning lathe machine. Contact us now, you can get a customized solution for vertical turning lathe machine, and you can also enjoy the exclusive discount for the first order of vertical turning lathe machine! Act now and let vertical turning lathe machine help your business develop efficiently!