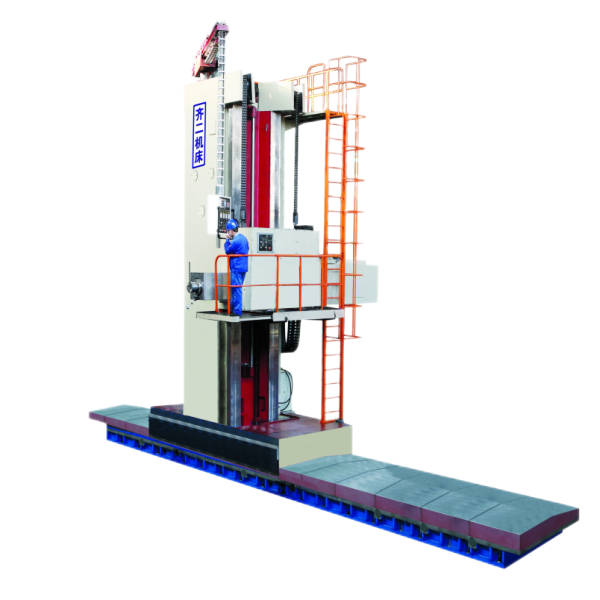

FA Series CNC Floor Type Milling And Boring Machine

Brand QIER WAJI CNC MACHINE

Product origin CHINA LIAONING

Delivery time 3 months

Supply capacity 2-5 units per month

1. FA series floor type milling and boring machine has the advantages of seven-axis control, arbitrary four-axis linkage; high speed, high precision, high efficiency and so on.

2. The FA series floor type milling and boring machine has high power and rigidity, which can not only meet the requirements of high-torque machining, but also be used for high-speed, high-precision light alloy processing. Installing various accessories can expand the machine tool. Processing range.

Cost advantages of FA series floor type milling and boring machine:

Rising electricity prices and labor costs are hurting your profits. Our FA series floor type milling and boring machine was designed to face this challenge. FA series floor type milling and boring machine adopts high-performance servo drive technology, which can reduce energy consumption during no-load and standby. At the same time, FA series floor type milling and boring machine significantly reduces the dependence of equipment on senior technicians and the required maintenance working hours through simplified maintenance design and automated processing processes. Using FA series floor type milling and boring machine can directly reduce operating costs for you.

Production capacity advantages of horizontal floor type boring machines:

Are you struggling with the old machine tools in the workshop that have been in service for 20 years, are inefficient and have lost accuracy? Our horizontal floor type boring machines are the perfect alternative solution. Horizontal floor type boring machines can not only perfectly undertake all traditional machining tasks, but also through modern CNC systems, higher cutting speeds and automation integration capabilities, your production capacity and accuracy can be significantly improved, and the investment cost of horizontal floor type boring machines is much lower than that of similar new equipment in Europe.

Specifications of FA series floor type milling and boring machine:

Specification /Model | Unit | FA-130 | FA-160 |

Boring Spindle Diameter | mm | 130 | 160 |

Milling Spindle End Diameter | mm | 221.44 | 254 |

Ram Section (W×H) | mm | 385×450 | 420×440 |

Spindle Taper | ISO50 | ISO50 | |

Column Travel (Axis X) | mm | 4000 | 8000 |

Headstock Travel (Axis Y) | mm | 2000 | 3000 |

Boring Spindle Travel (Axis Z) | mm | 800 | 1100 |

Ram Travel (Axis W) | mm | 700 | 1000 |

Spindle Speed | r/min | 10-2500 | 10-2000 |

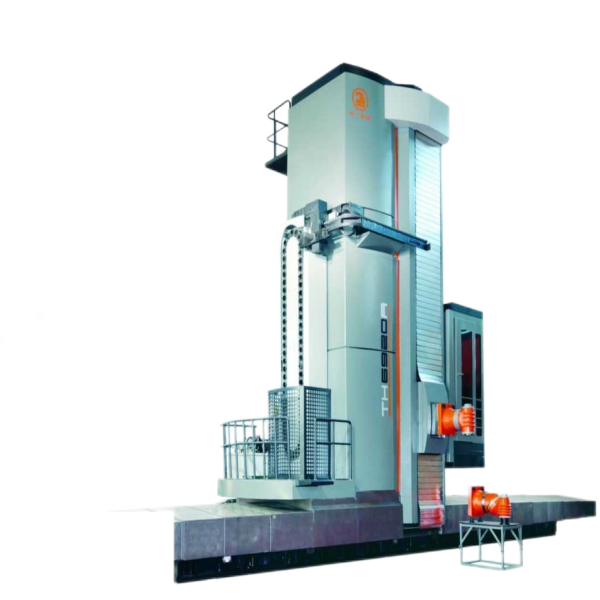

Introduction of CNC Horizontal boring milling machines:

CNC Horizontal boring milling machines is designed and manufactured by adopting new technologies such as modern machinery, electricity and hydraulics. CNC Horizontal boring milling machines can realize multi-axis control and any four-axis linkage function. After the workpiece is clamped once, it can complete drilling, reaming, boring, groove cutting, plane milling, and boring or milling of three-dimensional curved surfaces and internal threads, which can effectively shorten the auxiliary time, realize one clamping, and more Process processing. It is an indispensable processing equipment for industrial sectors such as heavy machinery, construction machinery, rolling stock, mining equipment, large motors, water turbines, steam turbines, ships, steel, military, nuclear power, large-scale environmental protection equipment, etc. Especially when used in conjunction with a variety of special accessories (vertical milling head, universal milling head, extension milling head, flat turntable, etc.), it can further expand the range of machine tools.

Performance advantages of horizontal floor type boring machines:

In the processing of heavy-duty workpieces, the stability and rigidity of the equipment are very important. Our horizontal floor type boring machines are designed with a floor-standing structure, with a low center of gravity and a large contact area with the ground, which can fundamentally reduce processing vibration. Even in the face of strong cutting of large workpieces, horizontal floor type boring machines can easily cope. The key components of horizontal floor type boring machines, such as the bed and the column, are all made of high-strength cast iron materials, which have undergone strict aging treatment to eliminate internal stress and are not easy to deform after long-term use. This solid structural design allows horizontal floor type boring machines to maintain stable and reliable performance during long-term and high-intensity processing tasks. Horizontal floor type boring machines can provide a solid processing guarantee for heavy-duty processing needs in aerospace, energy equipment and other fields.

Multi-scene fast switching capability of CNC horizontal boring milling machines:

Our CNC horizontal boring milling machines use modular and fast switching capabilities to provide important support for enterprises to efficiently respond to complex production needs. CNC horizontal boring milling machines adopts a standardized interface design, which supports the rapid disassembly and switching of core process modules such as milling, boring, drilling, and grinding. Through a special hydraulic or pneumatic locking device, the operator can complete the module replacement of CNC horizontal boring milling machines within 15 minutes without complicated debugging and reduce downtime for production replacement. Whether it is precision milling tasks in the aerospace field or heavy-duty boring in the energy equipment industry, CNC horizontal boring milling machines can quickly adapt to different working conditions, helping enterprises flexibly allocate production capacity, improve production line utilization and delivery efficiency, and seize the opportunity in the market competition.

The speed of getting started with CNC horizontal boring milling machines:

The most expensive cost of introducing new equipment is usually personnel training and a long learning curve. Our CNC horizontal boring milling machines are equipped with mainstream CNC systems that your team is already familiar with, such as Siemens and Fanuc. CNC horizontal boring milling machines are also equipped with a clear multilingual interface and an ergonomic operation station. Your existing team can get started quickly with almost no additional training, maximizing the productivity loss during the adaptation period, and purchasing CNC horizontal boring milling machines will make your investment pay off quickly.

Long-term service of boring mills horizontal floor type:

Your main business is to manufacture excellent products, not to repair boring mills horizontal floor type. What we provide is not only a boring mills horizontal floor type, but also a worry-free solution. The reliable performance of boring mills horizontal floor type eliminates the need to worry about unplanned downtime. Boring mills horizontal floor type's clear maintenance guidelines make it easy for your team to maintain. Fast remote support for boring mills horizontal floor type can solve most questions in an instant. Let us deal with the complexity of boring mills horizontal floor type management and help you focus all your energy on your core business growth.

Other models of FA series CNC floor type milling and boring machine:

FA130 series CNC floor type milling and boring machine,

FA160 series CNC floor type milling and boring machine.

Application of FA series floor type milling and boring machine:

1. Parts produced in small batches and multiple times.

2. Parts with complex shapes and high machining accuracy that cannot be machined by general-purpose machine tools or are difficult to guarantee the machining quality.

3. In the process of processing, multi-process processing must be carried out, such as milling, boring, countersinking or tapping must be completed in one clamping.

4. Parts for which tolerances must be strictly controlled.

5. Workpieces with large cutting allowance.

6. Shell or box-shaped parts with difficult to measure, difficult to control feed, and difficult to control cavity size.

7. Parts whose process and design will change.

FAQ:

Q1: What types of workpieces is boring mills horizontal floor type suitable for machining?

A: Boring mills horizontal floor type is suitable for processing large and heavy workpieces. Boring mills horizontal floor type has powerful cutting capabilities and large stroke characteristics, which can meet the needs of complex surface milling, deep hole boring, high-precision hole system machining and other processes.

Q2: Compared with ordinary milling and boring machines, what are the advantages of boring mills horizontal floor type?

A: Boring mills horizontal floor type realizes automated processing through a CNC system, which has functions such as high-precision positioning, multi-axis linkage, and program presets, which can reduce manual operation errors and improve processing efficiency and accuracy. At the same time, boring mills horizontal floor type supports one-time clamping of complex parts to complete multiple processes, which can shorten the production cycle and reduce the scrap rate.

Q3: What aspects do you need to pay attention to in the daily maintenance of horizontal floor type boring machines?

A: It is necessary to check the rail lubrication system and spindle cooling system of CNC floor-standing milling and boring machines regularly every day to keep the oil circuit smooth. It is also necessary to clean the horizontal floor type boring machines screws, chips and oil stains on the surface of the guide rail to prevent wear. The CNC system parameters of horizontal floor type boring machines should be calibrated regularly to ensure machining accuracy.

Q4: Can horizontal floor type boring machines be adapted to the processing of different materials?

A: Yes. Horizontal floor type boring machines supports the processing of a variety of materials, including alloy steel, stainless steel, cast iron, etc. By adjusting the tool type, cutting parameters and selection of suitable cooling and lubrication schemes of horizontal floor type boring machines, the processing needs of materials of different hardness and toughness can be met, and the surface quality and processing efficiency can be guaranteed.

Company profile:

QIER MACHINE GROUP DALIAN WAJI CNC MACHINE Co., Ltd. is a joint-stock enterprise jointly invested by QIER Machine Group affiliated to China General Technology Group and the former DALIAN WAFANGDIAN MACHINE GROUP Co., LTD., (WAFANGDIAN HEAVY MACHINE) in 2003. The company is located in Dalian Changxing Island industrial park, the beautiful shore of Bohai Sea. Our company registered paid-in capital of 80 million, factory covers an area of 13 acres that is a modern garden factory.

Based on the advantage of technology, manufacturing and service, our company establish own developing direction, which is user-centered, guided by the marketing, persisted in the innovation of technology, continuously developing modularized and multi-functional products. Our company has already formed the new mechanism of self-reliance and innovation and working hard to develop high level reliable and fitness products.

The company take the initiative in the market and widely satisfaction the requirement raised by user, so far, have already continuously developed over 10 different kinds of CNC machines which have been widely used in the shipping industry, electricity generating and so on, in particular, the developing of vertical CNC multifunctional milling and boring machine has replaced the same type of abroad imported products in China.

The company has already had a sales network spread all over China. We will keep our promise, good quality of products and have courage to take responsibility. Sincerely hope we can supply the best products, the best service in the most competitive price. Hoping establish multi-mode cooperation with new and old friends all around the world.