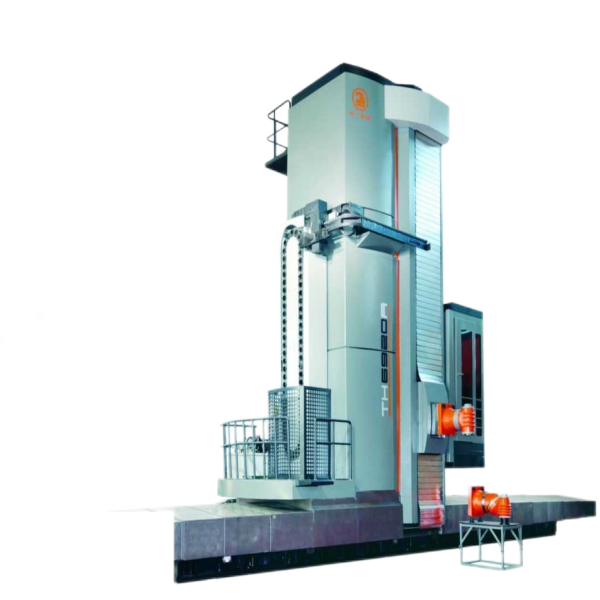

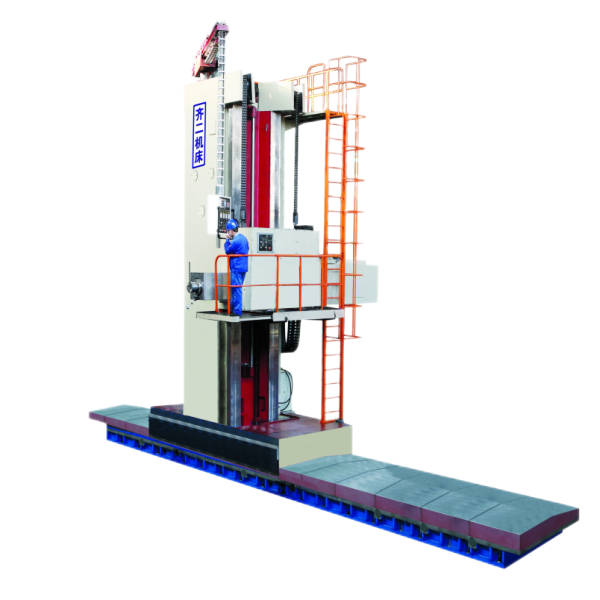

TKA69 Series CNC Floor Type Milling And Boring Machine

Brand QIER WAJI CNC MACHINE

Product origin CHINA LIAONING

Delivery time 3 months

Supply capacity 2-5 units per month

1. Floor type boring machine has good wear resistance and shock absorption.

2. Floor type boring machine has large low frequency torque and stable output.

3. Floor type boring machine decelerates and stops quickly.

4. Floor type boring machine has fast torque dynamic response and high speed stabilization accuracy.

Heavy-duty processing capacity of floor type boring machine:

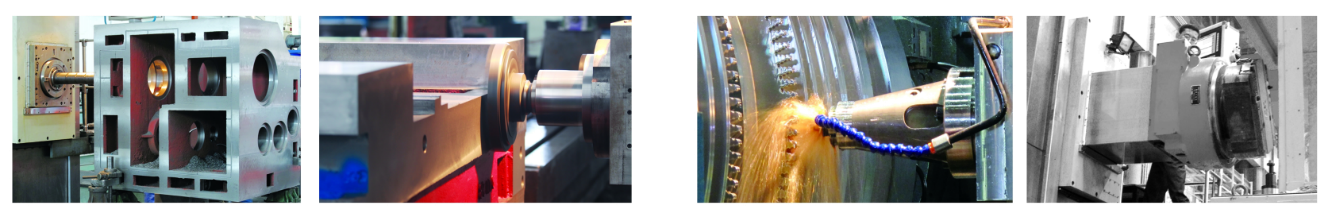

Floor type boring machine has an industry-leading oversized stroke, which can easily accommodate and process large workpieces. Floor type boring machine can meet the processing needs of large-size parts such as wind power equipment and ship parts. At the same time, new floor type milling machine are equipped with a high-power spindle and a high-torque feed system, which can withstand high workpiece weight. During heavy-duty cutting, new floor type milling machine can maintain stable accuracy and efficient processing speed, far exceeding the load capacity of similar products.

The composite processing capability of milling machines:

Milling machines integrates milling, boring, drilling, tapping and other processing functions in one. Milling machines realizes the whole process processing of complex workpieces through automatic tool change and process switching. The use of milling machines can reduce equipment investment and workpiece turnover, and the use of milling machines can improve workshop space utilization and production efficiency.

Specifications of boring and milling machines:

Specification/Model | Unit | K6913B/TH6913B | TK6916B/TH6916B | TK6916/TH6916 | TK6920/TH6920 | TK6920A/TH6920A | TK6926B/TH6926B | TK6932/TH6932 |

Boring Spindle Diameter | mm | Φ130 | Φ160 | Φ160 | Φ200 | Φ200 | Φ260 | Φ320 |

Boring Spindle Taper (7:24) | ISO50 | ISO50 | ISO50 | ISO60 | ISO50 | ISO60 | ISO60 | |

Milling Spindle End Diameter | mm | Φ254 | Φ280 | Φ320 | Φ320 | Φ320 | Φ400 | Φ450 |

Ram Section | mm | 380×400 | 440×480 | 480×520 | 480×520 | 480×520 | 600×650 | 680×780 |

Column Travel ( can be extended) Axis X | mm | 4000 | 6000 | 6000 | 8000 | 8000 | 10000 | 18000 |

Headstock Travel (can be extended) Axis Y | mm | 2000 | 3000 | 3000 | 4000 | 4000 | 5000 | 8000 |

Boring Spindle Travel (Axis Z) | mm | 700 | 1000 | 1200 | 1200 | 1200 | 1700 | 1800 |

Ram Travel (Axis W) | mm | 900 | 1000 | 1200 | 1200 | 1200 | 1700 | 2000 |

Headstock Speed Range, III Shifts | rpm | 2-1500/3.2-2500 | 2-1500 | 2-1000 | 2-1000 | 2-2500 | 2-800(1000) | 2-600 |

Feed Rate of Boring Spindle and Ram, Infinitely Variable | mm/min | 0.6-8000 | 0.6-4000 | 1-3000 | 1-3000 | 1-10000 | 1-3000 | 1-3000 |

Feed Rate of Column and Headstock, Infinitely Variable | mm/min | 1-8000 | 1-6000 | 1-6000 | 1-6000 | 1-15000 | 1-6000 | 1-6000 |

Main Motor Power | kw | 37 | 60 | 55 | 71 | 60 | 100 | 129 |

Tool Magazine Capacity | Pc. | 40 (For Machining Center) | 60 (Machining Center) | 60 (Machining Center) | 60 (Machining Center) | 60-100 | 60 (Machining Center) | 80 (Machining Center) |

Introduction of the application and characteristics of floor type milling machine:

It adopts headstock structure with moving ram for both CNC floor type milling and boring machines, series TK69 and CNC floor type milling and boring machining center, series TH69. Our company independently developed those milling machines with independent intellectual property. Those milling machines have reliable performance with the application of multiple advanced technologies, such as the double pinion and rack backlash free structure or dual motor with double pinion and rack transmission provided for Axis X. There are preloaded backlash-free high precision ball-screw trans mission structure provided for Axes Y, Z and W. The multi-pocket closed hydrostatic guideways structure is applied on the guideways of the Axes Y, Z and W, which has low difference between dynamic and static friction coefficients and no stick and slip at low speed. The pressure in each hydrostatic oil pocket is controlled by the damper with capillary spiral tubes, which have features of simple structure, small occupying space, and convenient adjustment. The CNC systems on those machines is capable of simultaneous motion control on any four axes and simultaneous five axes motion control, if the high precision two-axes swivel milling head is mounted. Those milling machines are equipped with vertical milling head, universal milling head, extended milling head and CNC rotary table, and they are especially appli cable for machining super heavy-duty workpieces with complex contour shapes. Those milling machines can accomplish milling, boring, taping, and machining of contour surfaces and lines in 5-D coordinate system (eg. propeller blades, etc.) with high precision and rigidity, and they are the hydro- mechatronic products integrated with high automation and technologies.

The machines of series TK69 and TH 69 are the key equipments urgently required in domestic heavy-equipment and important industries. This series of new floor type milling machine are first developed and produced in the domestic market of China and they can replace the machines imported from overseas suppliers. New floor type milling machine have reached the advanced level of similar products contemporarily around the world, with much lower market prices. Our company provide after sales services and spare parts in time after the request received and we deliver the services and parts much faster than the foreign suppliers do. Thus, this series of floor type milling machine have strong competitiveness in the international market. Those floor type milling machine can be widely applied in military industry, energy industry, wind power industry, nuclear power industry, metallurgy industry, shipbuilding industry, airspace and aviation industry, transportation industry and important machinery manufacturing industry of the nation.

Modular and compatible design of milling machines:

Milling machines breaks through the adaptation limitations of a single industry of traditional machine tools and adopts a modular core component design. Milling machines can quickly replace the spindle unit, workbench fixture and tool library, and realize the seamless switching of multi-industry processing scenarios such as aerospace precision structural parts and new energy vehicle molds. Using milling machines, there is no need to purchase multiple equipment separately, which can greatly improve asset utilization. Milling machines is especially suitable for the flexible production needs of multi-category orders from European and American companies.

Multilingual intelligent interaction of milling machines:

Milling machines is equipped with an intelligent multi-language interactive system that supports a variety of mainstream European and American languages. Milling machines' system has a built-in industry professional term base to help accurately convey operating instructions. At the same time, the operation interface of milling machines has been optimized and designed according to the operating habits of European and American users, simplifying the level of complex functions. New employees can quickly get started with basic operations within 30 minutes through visual icon guidance, which significantly reduces the cost of language learning and the risk of operational errors.

Innovative process customization of milling machines:

We have an in-depth understanding of the processing characteristics of different industries in Europe and the United States, such as high-precision curved surface processing in the manufacture of auto parts, deep-hole processing of thick-walled parts in the manufacture of energy equipment, etc., and provide exclusive customized milling machines processing technology solutions. These milling machine solutions are formulated by our team of senior process experts combined with advanced processing simulation software, so that milling machines can accurately overcome various complex processing problems and improve processing efficiency and yield.

Data and privacy security of milling machines:

In view of the strict requirements of European and American companies for data security, the control system of milling machines adopts an encrypted transmission protocol, and the storage of production data complies with EU regulations. Milling machines only opens data access rights to personnel authorized by the buyer, eliminating the leakage of core information such as processing parameters and production plans, and allowing milling machines to help enterprises produce safely.

Comparative advantages of milling machines:

1. Compared with horizontal milling and boring machines, milling machines adopts a floor-standing body design. There is no fixed workbench, and the bed can be installed directly on the ground. The overall structure of new floor type milling machine is larger and more rigid. The headstock of new floor type milling machine can be moved up and down along the column, with a large beam or ram, which is suitable for carrying heavy workpieces.

2. New floor type milling machine are designed for ultra-large and ultra-heavy workpieces. New floor type milling machine can easily carry major workpieces. The bed and workbench of new floor type milling machine also have good load-bearing capacity, and even if high-intensity cutting is carried out, it can maintain extremely high stability. The workbench of milling machines is suitable for powerful milling and deep hole boring of high-strength materials, and milling machines can realize the integrated processing of full-size coverage of the workpiece, reducing the errors caused by multiple clamping.

3. The applicable industries and scenarios of new floor type milling machine are focused on heavy-duty industrial fields, new floor type milling machine can solve the one-time clamping and processing needs of heavy and large workpieces.

Advantages of floor type boring machine:

1. Guideways on slide, ram, headstock and other moving components are all provided with closed hydrostatic guideways with multi-pocket, which ensure low difference between dynamic and static friction coefficients and eliminates the stick and slip at low speed. The hydrostatic guideways also have the advantages of high anti-overturn moment and wear-resistance and elimination of thermal deformation of the machine.

2. The scales from qualified and professional manufacturers both in China and aboard are provided for the motions along the Axes X, Y and W for the full close loop control. The encoder is provided on Axis Z for the half close loop control.

3. The floating clamping device is provided for the clamping on the linear motion of column, ram and headstock with rapid and reliable clamping actions. The hydrostatic oil film will not be damaged at the clamping status, and the clamping and unclamping is interlocked with electrical control system.

4. The spindle tool is clamped by a set of disc springs and released by hydraulic pressure, which is safe, fast and reliable.

5. The hydraulic system of the machine is provided with full-closed central oil supply system, and equipped with oil cooler to control the tem perature of main spindle and the system.

6. The headstock of the machine is constructed in a closed structure. The ram is made from an integrated cast part and then finely machined. The ram has high rigidity, no deformation, and high machining reliability and accuracy for a long service life.

7. The spindle is made from qualified alloy steel and has been machined through multiple processes. The main spindle is from qualified and professional manufacturers from China and abroad, which ensures the accuracy of the main spindle.

Application areas of floor type boring machine:

1. Energy equipment manufacturing: floor type boring machine can process the core components of large-scale power station equipment. Floor type boring machine can meet the processing needs of deep holes, large-diameter inner holes and complex planes for heavy-duty components.

2. Aerospace and national defense industry: floor type boring machine can manufacture heavy military components such as aircraft engine casings, aircraft landing gear support structures, and missile launchers. Floor type boring machine can accurately complete the integrated processing of polyhedra, complex curved surfaces and high-precision hole systems.

3. Heavy-duty trucks and mechanical engineering: floor type boring machine can produce heavy-duty truck frame beams, gearbox housings, crane boom, slewing bearing seats and other important components. Floor type boring machine can efficiently complete the milling, boring and threading of thick-walled parts, improving the carrying capacity and durability of construction machinery.

4. Mold and large-scale machine tool manufacturing: floor type boring machine can process mold frames for large stamping molds and cavity templates for injection molds. At the same time, floor type boring machine are also used to manufacture basic components such as beds and columns of other large machine tools. With high-precision machining capabilities, floor type boring machine can guarantee the accuracy of mold forming and the operating stability of the machine tool itself.

Quality assurance of new floor type milling machine:

Every milling machine we produce will undergo rigorous testing to simulate extreme environments such as high humidity, strong electromagnetic interference, and ultra-low temperature before leaving the factory, so that floor type boring machine can operate stably under various complex working conditions around the world. In addition, new floor type milling machine has passed CE, UL and other authoritative certifications in Europe and the United States. From design, material selection to production, every link strictly follows international standards, and the quality is reliable, allowing European and American buyers to purchase and use with confidence.

The green concept of milling machines:

Milling machines use energy-saving design and recyclable materials. The energy consumption of milling machines complies with the EU ERP Energy Efficiency Directive. The production process of milling machines has passed the ISO 14001 environmental management system certification. Milling machines can help companies build a green supply chain, improve ESG performance, and strengthen brand social responsibility and market competitiveness.

Our strengths:

As a leading enterprise in the domestic machine tool industry, we have many years of R&D and manufacturing experience in new floor type milling machine, and have served more than a thousand global companies. Our large-scale intelligent manufacturing base is equipped with internationally advanced precision processing equipment and automated production lines, and its annual production capacity ranks firmly in the forefront of the industry. The base has passed the ISO 9001 quality management system certification, so that the quality of floor type boring machine is stable and consistent.

FAQ:

Q1: What are the requirements for the installation environment of the milling machines?

A: The milling machines needs to be installed on a solid, flat cement floor to prevent it from approaching the vibration source. The installation ambient temperature of the milling machines needs to be controlled at 15 to 30℃, and the humidity should be maintained at 40% to 60% to avoid dust and corrosive gases. At the same time, the installation of the milling machines requires an independent regulated power supply to prevent voltage fluctuations from affecting the operation of the milling machines.

Q2: Can the function of new floor type milling machine be customized according to the special processing needs of the enterprise?

A: Yes. Floor type horizontal boring machine supports the development of customized functions, such as adding a CNC rotary table to achieve five-sided machining, installing an automatic tool change system to improve efficiency, etc. According to the specific process needs of the enterprise, we will work with the technical team to formulate a customized plan for the new floor type milling machine, so that the new floor type milling machine can be adapted to production scenarios.

Q3: When a novice operates, how can I avoid damage to the floor type horizontal boring machine or scrap processing due to operation errors?

A: It is recommended that novices first pass the simulation operation function of the floor type horizontal boring machine to verify whether the machining program path of the floor type horizontal boring machine is reasonable without clamping the workpiece or starting the spindle. When operating the floor type horizontal boring machine, strictly abide by the principle of low-speed trial cutting. For the first time, the lower speed and feed speed are used for the first processing. After the trial cutting, the size is measured, and the parameters of the floor type horizontal boring machine are confirmed to be correct. Gradually increase the parameters of the floor type horizontal boring machine, while keeping in mind the position of the emergency stop button, and stop immediately if you encounter an abnormality.

Q4: When machining workpieces of different hardness, in addition to changing tools, which floor type horizontal boring machine settings need to be adjusted?

A: The cutting parameters in the CNC system of the floor type horizontal boring machine need to be adjusted correspondingly. For example, when machining high-hardness materials, the spindle speed should be reduced and the feed should be reduced to avoid tool overload. When processing soft materials, the speed and feed speed of the floor type horizontal boring machine can be appropriately increased to improve efficiency. At the same time, the cooling system of the floor type horizontal boring machine needs to be adjusted. The processing of high-hardness materials can increase the coolant flow and enhance the cooling and chip removal effect. Soft materials can adjust the cooling method of the floor type horizontal boring machine according to demand.

Q5: I have not used the floor type horizontal boring machine for a long time. What preparations do I need to make before activating it again?

A: First check the appearance of the floor type horizontal boring machine and whether the parts are intact, and clean up the dust and anti-rust oil on the surface of the guide rail and screw. Manually rotate the spindle and each axis of the floor type horizontal boring machine to check for any stagnation. After starting the floor type horizontal boring machine, let each axis run without load for 10 to 15 minutes, and turn on the lubrication system at the same time to evenly distribute the lubricating oil. Check whether the coolant has deteriorated. If it has expired, you need to replace the floor type horizontal boring machine with a new coolant, and finally calibrate the tool and workpiece coordinate system before processing.

About packaging:

We choose to ship by sea, and the packaging is firm to ensure that your goods arrive safely and quickly. The delivery time is generally about 1.5~6 months. Regarding the payment method, you need to pay 30% in advance, and 70% of the balance can be paid before delivery.

Now, the manufacturing industry in Europe and the United States pursues high efficiency, precision and sustainable development. With excellent performance and innovative technology, our floor type boring machine can become your first choice to improve your competitiveness! Our floor type boring machine can ensure the stability and high precision of long-term processing. Floor type boring machine adopts a unique cast oil return pipe design to solve the hidden dangers of oil spills in the industry and improve equipment reliability. New floor type milling machine are widely used in energy, shipbuilding, aerospace and other fields. New floor type milling machine can easily complete multi-process processing such as milling, drilling, reaming, tapping and boring. Whether it is high-precision hole system or large-diameter hole system processing, new floor type milling machine can handle it with ease. Through the optional special accessories, new floor type milling machine can also realize five-axis linkage to meet the processing needs of complex parts. From the installation and commissioning of floor type boring machine to intelligent upgrades, we provide full life cycle services. Contact us now and let floor type boring machine help your business take to new heights!