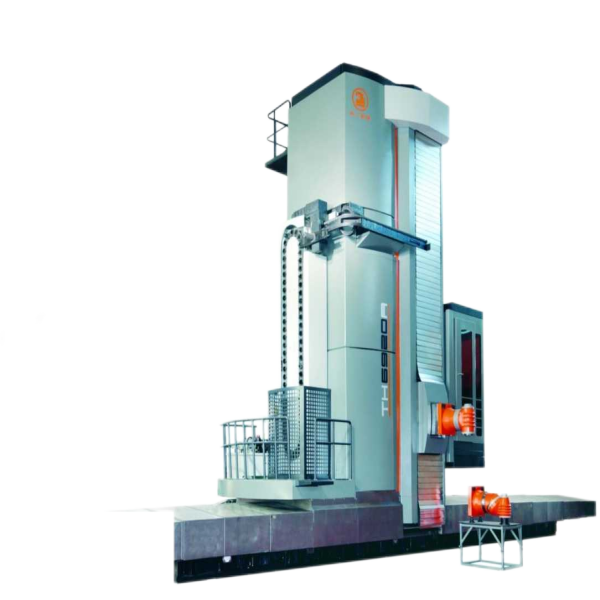

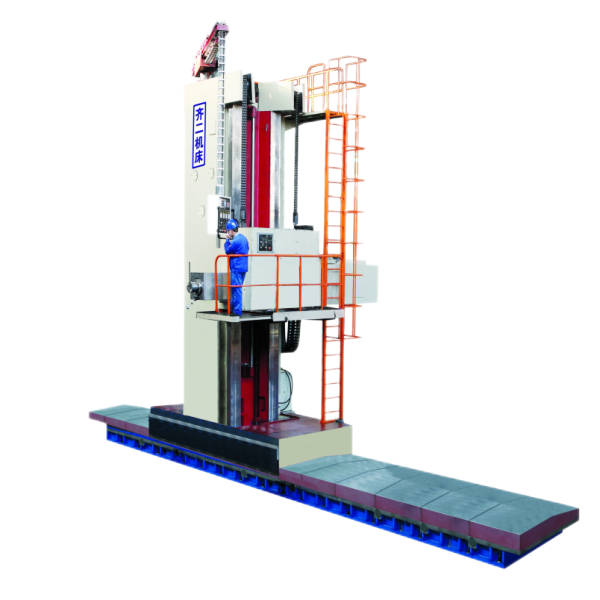

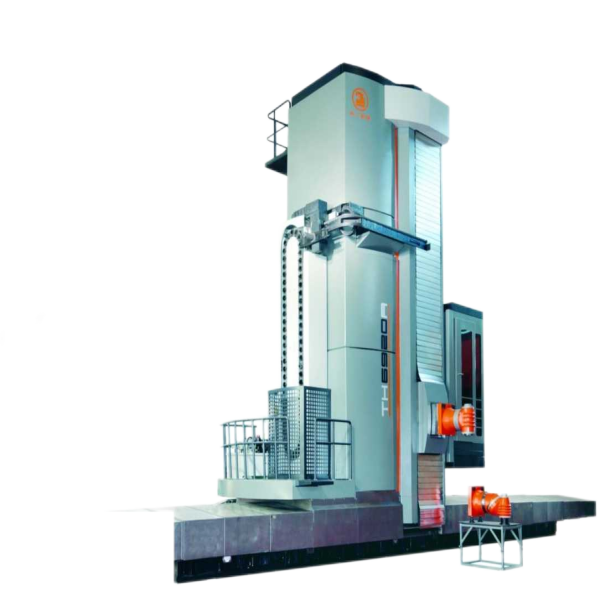

TK69 Series CNC Floor Type Milling And Boring Machine

Brand QIER WAJI CNC MACHINE

Product origin CHINA LIAONING

Delivery time 3 months

Supply capacity 2-5 units per month

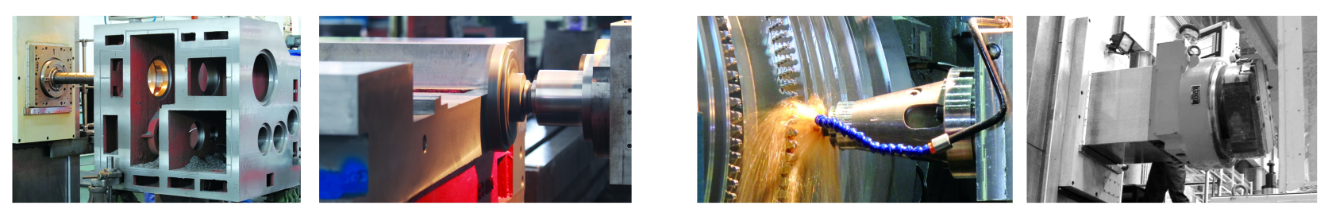

1. Floor type milling machine has a high-speed, high-power, and high-torque spindle system, which can easily cut all kinds of metal materials.

2. Floor type milling machine can realize various operations such as drilling, reaming, boring, grooving, plane milling, etc. with one clamping, and can also process high-precision hole systems and large-diameter hole systems.

Cultural adaptation services of boring mills:

Service details that span cultural differences are the key to ensuring the efficient application of boring mill. For European and American buyers, we have built a comprehensive cultural adaptation service system. The technical service team has received systematic cross-cultural communication training to understand the workflow and communication habits of European and American companies, reduce the deviation of demand understanding, and make the service response more efficient. The user interface of boring mill adopts icons and layout that conform to the aesthetics of European and American industrial design, and the professional terminology strictly follows international standards such as ASME and ISO. Boring mill is simple to operate, and operators can quickly become familiar with the functions. Whether it is technical consultation or remote guidance, we will use culturally appropriate service details to create a good boring mill experience for you. Reduce communication barriers and the use of boring mill caused by cultural differences.

Specifications of boring mill:

Specification/Model | Unit | K6913B/TH6913B | TK6916B/TH6916B | TK6916/TH6916 | TK6920/TH6920 | TK6920A/TH6920A | TK6926B/TH6926B | TK6932/TH6932 |

Boring Spindle Diameter | mm | Φ130 | Φ160 | Φ160 | Φ200 | Φ200 | Φ260 | Φ320 |

Boring Spindle Taper (7:24) | ISO50 | ISO50 | ISO50 | ISO60 | ISO50 | ISO60 | ISO60 | |

Milling Spindle End Diameter | mm | Φ254 | Φ280 | Φ320 | Φ320 | Φ320 | Φ400 | Φ450 |

Ram Section | mm | 380×400 | 440×480 | 480×520 | 480×520 | 480×520 | 600×650 | 680×780 |

Column Travel (can be extended) Axis X | mm | 4000 | 6000 | 6000 | 8000 | 8000 | 10000 | 18000 |

Headstock Travel (can be extended) Axis Y | mm | 2000 | 3000 | 3000 | 4000 | 4000 | 5000 | 8000 |

Boring Spindle Travel (Axis Z) | mm | 700 | 1000 | 1200 | 1200 | 1200 | 1700 | 1800 |

Ram Travel (Axis W) | mm | 900 | 1000 | 1200 | 1200 | 1200 | 1700 | 2000 |

Headstock Speed Range, III Shifts | rpm | 2-1500/3.2-2500 | 2-1500 | 2-1000 | 2-1000 | 2-2500 | 2-800(1000) | 2-600 |

Feed Rate of Boring Spindle and Ram, Infinitely Variable | mm/min | 0.6-8000 | 0.6-4000 | 1-3000 | 1-3000 | 1-10000 | 1-3000 | 1-3000 |

Feed Rate of Column and Headstock, Infinitely Variable | mm/min | 1-8000 | 1-6000 | 1-6000 | 1-6000 | 1-15000 | 1-6000 | 1-6000 |

Main Motor Power | kw | 37 | 60 | 55 | 71 | 60 | 100 | 129 |

Tool Magazine Capacity | Pc. | 40 (For Machining Center) | 60 (Machining Center) | 60 (Machining Center) | 60 (Machining Center) | 60-100 | 60 (Machining Center) | 80 (Machining Center) |

Other products of the same series of floor type milling machine:

TKA6913B series CNC floor type milling and boring machine,

TKA6916B series CNC floor type milling and boring machine,

TKA6916 series CNC floor type milling and boring machine,

TKA6920 series CNC floor type milling and boring machine,

TKA6920A series CNC floor type milling and boring machine,

TKA6926B series CNC floor type milling and boring machine,

TKA6932 series CNC floor type milling and boring machine.

Introduction of the application and characteristics of floor type milling machine:

It adopts headstock structure with moving ram for both CNC floor type milling and boring machines, series TK69 and CNC floor type milling and boring machining center, series TH69. Our company independently developed those machines with independent intellectual property. Those machines have reliable performance with the application of multiple advanced technologies, such as the double pinion and rack backlash free structure or dual motor with double pinion and rack transmission provided for Axis X. There are preloaded backlash-free high precision ball-screw transmission structure provided for Axes Y, Z and W. The multi-pocket closed hydrostatic guideways structure is applied on the guideways of the Axes Y, Z and W, which has low difference between dynamic and static friction coefficients and no stick and slip at low speed. The pressure in each hydrostatic oil pocket is controlled by the damper with capillary spiral tubes, which have features of simple structure, small occupying space, and convenient adjustment. The CNC systems on those machines is capable of simultaneous motion control on any four axes and simultaneous five axes motion control, if the high precision two-axes swivel milling head is mounted. Those machines are equipped with vertical milling head, universal milling head, extended milling head and CNC rotary table, and they are especially applicable for machining super heavy-duty workpieces with complex contour shapes. Those machines can accomplish milling, boring, taping, and machining of contour surfaces and lines in 5-D coordinate system (eg. propeller blades, etc.) with high precision and rigidity, and they are the hydro- mechatronic products integrated with high automation and technologies.

The machines of Series TK69 and TH 69 are the key equipments urgently required in domestic heavy-equipment and important industries. This series of machines are first developed and produced in the domestic market of China and they can replace the machines imported from overseas suppliers. They have reached the advanced level of similar products contemporarily around the world, with much lower market prices. Our company provide after sales services and spare parts in time after the request received and we deliver the services and parts much faster than the foreign suppliers do. Thus, this series of machines have strong competitiveness in the international market. Those machines can be widely applied in military industry, energy industry, wind power industry, nuclear power industry, metallurgy industry, shipbuilding industry, airspace and aviation industry, transportation industry and important machinery manufacturing industry of the nation.

CNC floor type milling and boring machining center, series TH69, are not only provided with all the functions of the machines, series TK69, but also with automatic tool changing function, and the magazine capacity can be customized upon customer's request.

Operation and maintenance design of boring mill:

The location of boring mill's operation box is reasonably laid out, and the buttons are within reach. Boring mill's system interface supports multi-language switching, which can reduce the learning threshold of operators. Boring mill's lubrication points, hydraulic stations, electrical cabinets and other maintenance parts are easy to access, and daily inspection and maintenance work is simple and easy, effectively reducing boring mill's maintenance time and labor costs.

Process support of boring mill:

We not only sell boring mill, but also share knowledge. Purchasing boring mill can get the initial support we have accumulated for the mature processing process parameters of different materials. This provides you with a proven starting point for cutting. Boring mill can reduce your process test time and tool loss, and boring mill can also help you achieve high-quality machining faster.

Spare parts guarantee of floor type milling machine:

We use world-renowned and reliable supply chain systems, such as Siemens, Fanuc, etc. This means that by choosing floor type milling machine, you don't have to worry about the source, quality, and future availability of key components. We are committed to floor type milling machine's long-term supply of spare parts, and provide clear spare parts manuals and ordering channels. Floor type milling machine keeps your production activities from stagnating.

Heavy-duty cutting capacity of floor type milling machine:

The spindle system of the floor type milling machine has a sturdy structure. The floor type milling machine is supported by large-diameter, high-preload precision bearings and is driven by a high-power, high-torque servo motor, which can output sufficient cutting torque even at low speeds. The tool holder clamping mechanism of floor type milling machine is highly rigid and can effectively suppress vibration. This allows the floor type milling machine to easily cope with the roughing process of large cutting depth and large feed volume, as well as the cutting of difficult-to-process materials such as high-strength steel and stainless steel. The floor type milling machine significantly improves the material removal rate.

Composite processing capacity of floor type milling machine:

Floor type milling machine support five-axis linkage function, and the whole process of processing complex curved surfaces, oblique holes, and polyhedra can be completed through one clamping. Compared with traditional three-axis equipment, floor type milling machine can reduce clamping by 3 to 5 times. Floor type milling machine can greatly improve processing efficiency and shape and position tolerance accuracy.

Process adaptability of CNC floor type milling and boring machine:

CNC floor type milling and boring machine provide a variety of spindle aperture, stroke, torque and power configurations. You can choose the most matching CNC floor type milling and boring machine model according to the main machining object. The rich library of accessory heads is the standard configuration of CNC floor type milling and boring machine. With the CNC rotary table, it can be easily clamped to complete five-sided processing at a time. CNC floor type milling and boring machine are particularly suitable for multi-variety, small-batch production of complex production mode.

Thermal stability of new floor type boring milling machines:

In view of the thermal deformation problem caused by long-term processing, new floor type boring milling machines has adopted a number of practical and effective measures. The spindle system of new floor type boring milling machines is equipped with an independent circulating cooling machine, which can effectively control the spindle temperature rise. The guide rail and screw lubrication system of new floor type boring milling machines are equipped with an oil temperature cooling device to stabilize the oil temperature. In addition, new floor type boring milling machines can provide software-based thermal error compensation options, and dynamically correct the coordinate offset through the model algorithm to keep the size of the parts in batch processing consistent.

Accuracy retention of boring mill:

The basic parts of boring mill are made of high-strength and high-quality castings, and the internal rib structure has been precisely calculated and optimized, which has high inherent rigidity and vibration resistance. The ultra-wide rectangular guide rail used in boring mill has undergone ultra-audio quenching and precision grinding, and with forced lubrication, it can make the drag plate move smoothly and without crawling, laying a solid foundation for long-term stable machining accuracy. Even after years of heavy-duty cutting, boring mill can still reliably maintain its working accuracy.

Reliability of boring mill:

Boring mill's reliability is based on mature design and strict manufacturing processes. The key functional components of boring mill are made of well-known brand products that have been proven in the market for a long time. Boring mill will undergo strict air transfer testing and heavy-duty cutting specimen inspection before leaving the factory to ensure that what is delivered to your factory is a reliable boring mill with stable performance and can be put into production immediately.

Advantages of floor type milling machine:

1. Main transmission system of the machine is provided with multi-shift mechanical transmission and electric infinitely variable transmission, which provides a wide range of infinitely variable transmission for the main spindle. Main transmission motor is from qualified and professional manufacturers both in China and abroad.

2. The control system and the Servo motor of the machine is from quali fied and professional manufacturers both in China and aboard. The CNC system is capable of seven axes control and simultaneous control on any four of them.

3. There is the spindle orientation provided for the machine.

4. There are various compensation functions applied on the machine, and the application of the digital electro hydraulic proportional valves ensures the satisfaction of the requirements for spindle precision.

5. The spindle system is provided with independent cooling function, which can control the spindle temperature and ensure the spindle precision at high speed.

Application scenarios of new floor type boring milling machines:

1. Aerospace field: new floor type boring milling machines is used to process high-precision and complex components such as aviation engine casing and aircraft fuselage frame. New floor type boring milling machines can realize one-time clamping of multi-curved surfaces and oblique holes, and new floor type boring milling machines can meet the high-rigidity cutting needs of aviation-grade materials.

2. In the field of heavy machinery: new floor type boring milling machines can process the crusher frame of mining machinery and the hydraulic pump body of construction machinery. New floor type boring milling machines is suitable for difficult-to-process materials such as high-strength steel and wear-resistant cast iron. New floor type boring milling machines can achieve efficient forming of large-size workpieces.

3. Shipbuilding field: new floor type boring milling machines can process the cylinder blocks of ship engines and large flanges in the hull structure, etc. New floor type boring milling machines can handle ultra-long and ultra-wide workpieces, and new floor type boring milling machines can meet the strict requirements of the shipbuilding industry for component sealing and connection accuracy.

4. In the field of rail transit: new floor type boring milling machines can process bogie beams of high-speed rail or subway and load-bearing beams of rail vehicles. New floor type boring milling machines can complete the synchronous processing of multi-station hole systems and complex contours. New floor type boring milling machines can ensure the operating safety and durability of rail transit equipment.

About our strengths:

1. Customization ability: according to your specific processing needs, we can provide full-process customization services from new floor type boring milling machines parameter adjustment, special tool configuration to process programming. We have developed an exclusive five-axis linkage machining solution for new floor type boring milling machines for a European aviation parts manufacturer, which shortens the production cycle.

2. Long-cycle cost advantage: choosing our new floor type boring milling machines means choosing cost optimization for the whole life cycle. Our new floor type boring milling machines has excellent performance and reliability, and the average trouble-free running time far exceeds industry standards. New floor type boring milling machines through innovative tool management system and efficient cutting technology, the service life of the tool is 25% longer than that of similar products, significantly reducing the cost of consumables. At the same time, the new floor type boring milling machines adopts an energy-saving design, and its energy consumption is lower than that of traditional models, which can reduce long-term electricity consumption. From procurement, use to maintenance, we use facts and technology to prove that choosing our new floor type boring milling machines is to choose a more economical and efficient long-term return on investment.

About packaging:

We choose to ship by sea, and the packaging is firm to ensure that your goods arrive safely and quickly. The delivery time is generally about 1.5~6 months. Regarding the payment method, you need to pay 30% in advance, and 70% of the balance can be paid before delivery.