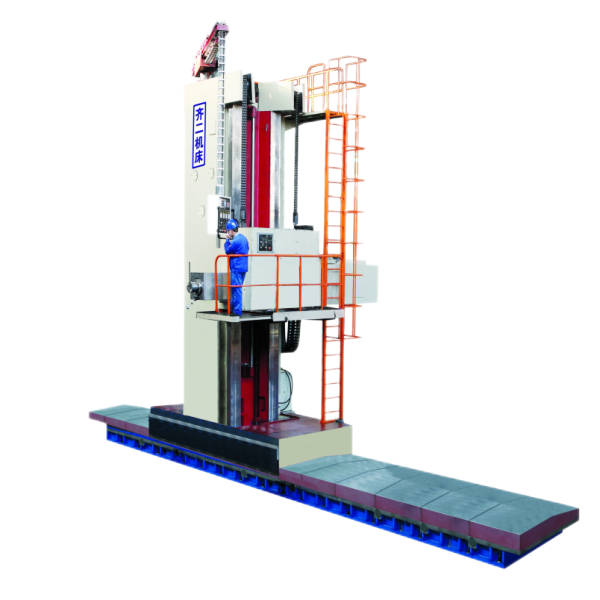

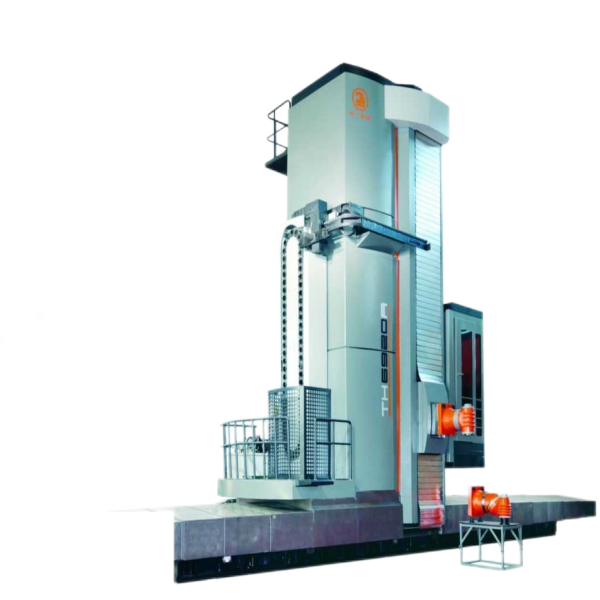

T69 Series Floor Type Milling And Boring Machine

Brand QIER WAJI CNC MACHINE

Product origin CHINA LIAONING

Delivery time 3 months

Supply capacity 2-5 units per month

1. The boring and milling machine is equipped with a semi-enclosed protective cover, which is beautiful, safe, leak-proof and protects the environment. Spiral automatic chip removal device (full protection) is simple and environmentally friendly, suitable for conveying general metal and non-metal chips.

2. Boring and milling machine has a high-efficiency automatic lubrication system: the guide rail lubrication adopts an electric pressure relief type lubrication pump, which has good lubricity and does not waste lubricating oil.

The milling and boring machine is specially tailored for small and medium-sized mass production. The milling and boring machine breaks the flexibility difficulties of traditional equipment through its modular design and quick change ability. Whether it is multi-variety switching or customized orders, our equipment can quickly respond to process requirements, significantly shorten production preparation time, and allow you to achieve efficient turnover in small and medium-sized batch processing scenarios, and calmly cope with changeable market orders.

Performance advantages of traveling column milling machine:

1. The traveling column milling machine adopts high-precision ball screws, linear guides and other transmission components to reduce mechanical transmission errors. At the same time, the bed is made of high-quality cast iron or age-treated materials, and the structural design is optimized through finite element analysis to improve the rigidity of the machine tool, suppress vibration and deformation, and allow the traveling column milling machine to maintain long-term stable machining accuracy.

2. The operation panel of the horizontal boring milling machine has a reasonable layout, which conforms to the principle of ergonomics and is convenient for operators to operate. In addition, the maintenance door of the horizontal boring milling machine floor type is reasonably designed to facilitate daily maintenance and overhaul by maintenance personnel.

3. Horizontal boring milling machine can provide personalized customized services according to the special needs of buyers. For example, according to the size and shape of the processed workpiece, special workbench, fixture and other components are customized. Or according to the buyer's production process and management requirements, the CNC system of the equipment is customized to meet the buyer's specific production needs.

Specifications of milling and boring machine:

Specification/Model | Unit | T6913D | T6916D | T6920D | T6926 |

Boring Spindle Diameter | mm | 130 | 160 | 200 | 260 |

Milling Spindle End Diameter | mm | 221.44 | 320 | 320 | 400 |

Ram Section (W x H) | mm | 350x380 | 480x520 | 480x520 | 600x650 |

Boring Spindle Taper | ISO-50 | ISO-50 | ISO-60 | ISO-60 | |

Boring Spindle Travel | mm | 800 | 1200 | 1200 | 1500 |

Ram Travel | mm | 700 | 1200 | 1200 | 1500 |

Headstock Travel (Can be Extended) | mm | 2000 | 3000 | 4000 | 5000 |

Column Travel (Can be Extended) | mm | 4000 | 6000 | 8000 | 10000 |

Spindle Speed Range (Infinitely Variable) | r/min | 3.15-750 | 2.3-485 | 2.3-485 | 1.6-500 |

Introduction of boring and milling machine:

Floor type milling and boring machine is the advanced equipments with wide application range and high product ion efficiency. After the completion of one-time workpiece setup, various operation, such as milling, boring and drilling, can be completed on the machine. The machine has the features of high efficiency, high precision and high versatility. The application of the machine can be increased with the installation of the optional accessories, such as universal milling head, vertical milling head, extended milling head, high speed milling head, swivel milling head, rear column, facing plate, rotary table.

Process characteristics of milling and boring machine:

1. Milling and boring machine can complete the multi-process processing of small and medium-sized workpieces such as milling, boring, drilling, and tapping without replacing equipment. It is especially suitable for the processing needs of multiple specifications in the same batch, and can avoid the loss of accuracy caused by the flow of multiple equipment.

2. For non-standard and complex workpieces common in small and medium-sized batches, the milling and boring machine can move or rotate through an independent workbench and cooperate with the multi-directional feed of the spindle to complete complex contour machining at once without segmented clamping, improving processing efficiency and accuracy consistency.

3. Compared with heavy-duty landing equipment, the energy consumption and footprint of the milling and boring machine for small and medium-sized batches are smaller, and there is no need to invest in heavy-duty hoisting equipment. Compared with horizontal milling and boring machines, milling and boring machine reduces the transportation and calibration costs of multi-process equipment replacement, and is more suitable for the low-cost and high-efficiency needs of small and medium-sized batch production.

Design of boring and milling machine:

From operation to maintenance, every design of the boring and milling machine is full of user-friendly considerations. The boring and milling machine has a reasonable layout with an ergonomic operation panel, and common functions are at your fingertips. With an intuitive graphical interactive interface and a multilingual system, even new employees can get started quickly. The maintenance area of the boring and milling machine adopts a convenient design, with spacious access channels and strong component accessibility, which significantly reduces the time and cost of daily maintenance and troubleshooting, so that both operators and maintenance personnel can feel efficient and convenient.

Green manufacturing of traveling column milling machine:

Traveling column milling machine has actively responded to the strict requirements of green manufacturing in the European and American markets, and practiced the concept of environmental protection throughout the life cycle of the equipment. The traveling column milling machine uses low-polluting materials and processes to reduce pollutant emissions in the production process from the source. The traveling column milling machine has an efficient automatic lubrication system, and the guide rail lubrication adopts an electric pressure relief lubrication pump, which has good lubricity and does not waste lubricating oil, which can reduce costs and environmental loads.

Certification of traveling column milling machine:

Horizontal boring milling machine floor type has passed UL, CE, GS and other authoritative certifications. From electrical safety to mechanical protection, every detail meets the compliance requirements of U.S. factories, helping you avoid the worries of equipment import approval and workshop deployment.

Other products in the same series of boring and milling machine:

T6913D series floor type horizontal boring milling machine floor type,

T6916D series floor type horizontal boring milling machine floor type,

T6920D series floor type horizontal boring milling machine floor type,

T6926 series floor type horizontal boring milling machine floor type.

Application field of boring and milling machine:

Boring and milling machine is widely used for medium and small batch processing of box parts, small plates, discs, shells, precision parts, etc. After the parts are clamped once, they can automatically complete multi-process processing such as milling, boring, drilling, expanding, reaming, and tapping.

Introduction of our factory:

QIER MACHINE GROUP DALIAN WAJI CNC MACHINE Co., Ltd. is a joint-stock enterprise jointly invested by QIER Machine Group affiliated to China General Technology Group and the former DALIAN WAFANGDIAN MACHINE GROUP Co., LTD., (WAFANGDIAN HEAVY MACHINE) in 2003. The company is located in Dalian Changxing Island industrial park, the beautiful shore of Bohai Sea. Our company registered paid-in capital of 80 million, factory covers an area of 13 acres that is a modern garden factory.

The company's sales network has spread all over the world. The company has always paid attention to human resource development and training to provide employees with a broad space for development. We will keep our promises, and take responsibility with excellent product quality. Sincerely hope that we can provide the best products and best services at the most competitive prices. Hope to establish multi-mode cooperation with old and new friends all over the world. Let us be a true partner.